Bag filter material

keyword:

Classification:

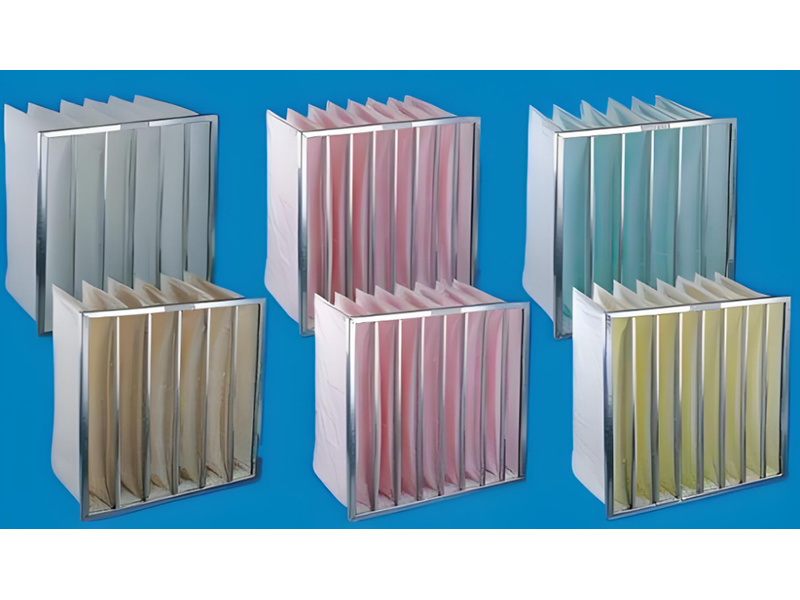

Bag filter material

A three-dimensional network is formed through a specific arrangement of fibers, which can effectively intercept dust particles in the air.

Structural characteristics

include fiber material and arrangement, layered structure and filter bag design, etc.:

● Fiber material and arrangement: glass fiber, polyester fiber and other materials are usually used, and these fiber materials are interwoven and arranged in a specific way to form a three-dimensional network structure, which can provide more stable filtration performance and adjust the fiber density as needed.

● Layered structure: Some filters adopt a layered design, with a lower outer density for initial interception of larger particles, and a higher inner density for capturing smaller particles, which can more effectively filter particles of different particle sizes.

● Filter bag design: Bag filters usually have multiple filter bags, and the number varies according to the specifications and uses. The mouth of the filter bag is sealed to prevent unfiltered air from leaking. Internal support structures such as metal or plastic gratings maintain the shape of the filter bags and ensure uniform filtration.

Application Scenarios

Bag filters are widely used in various occasions that require air purification, such as central air conditioning systems, ventilation systems, etc. Its role is to capture dust particles of 1-5 microns with an efficiency between 60% and 95%. Specific application scenarios include:

● Central air-conditioning system: filter indoor air and provide a clean indoor environment.

● Ventilation system: used in industrial plants, hospitals, laboratories and other places to ensure air quality.

● Other applications: in any occasion where air quality needs to be controlled, such as clean rooms, laboratories, etc.

Previous

Next

FAQ

Water leakage problem

Filter element damage: Due to too long use time, impact or improper installation, the filter element may be damaged, resulting in water leakage.

Loose interface: The seal between the filter element and the device interface may be loosened due to long-term use, resulting in water leakage.

Filter aging: After a long time of use, the polypropylene melt-blown filter may lose its original sealing performance due to the aging of the material, resulting in water leakage.

Degradation of filtration efficiency

Blockage: With the increase of use time, the filter element will gradually accumulate impurities in the water, resulting in blockage, which will affect its filtration efficiency.

Pollution: If the water quality is poor, the filter element may be seriously polluted, further reducing its filtration performa

Material problem

Corrosion resistance: Although polypropylene materials have good acid and alkali resistance, under certain extreme conditions (such as strong oxidizing environment), their corrosion resistance may be affected.

Safety: The raw materials of polypropylene meltblow filter should ensure that they are non-toxic and tasteless, but the products purchased in informal channels may have material safety problems, affecting the use effect and health.

Related products

CONSULT NOW

Filling in your phone and email information will help us get in touch with you in a timely manner and resolve your issue as soon as possible.